View Key Achievements Through Images

- All

- Chemical · Petrochemical

- Environmental · Energy

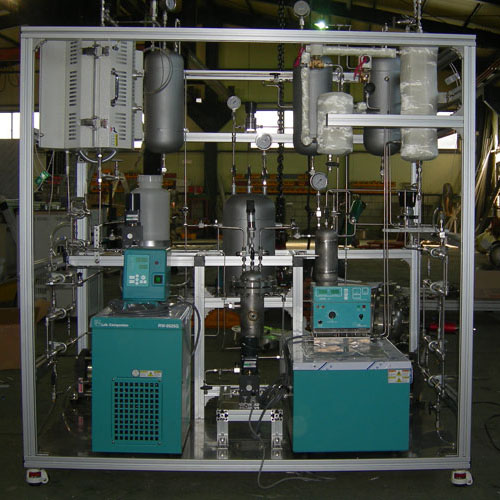

- Laboratories

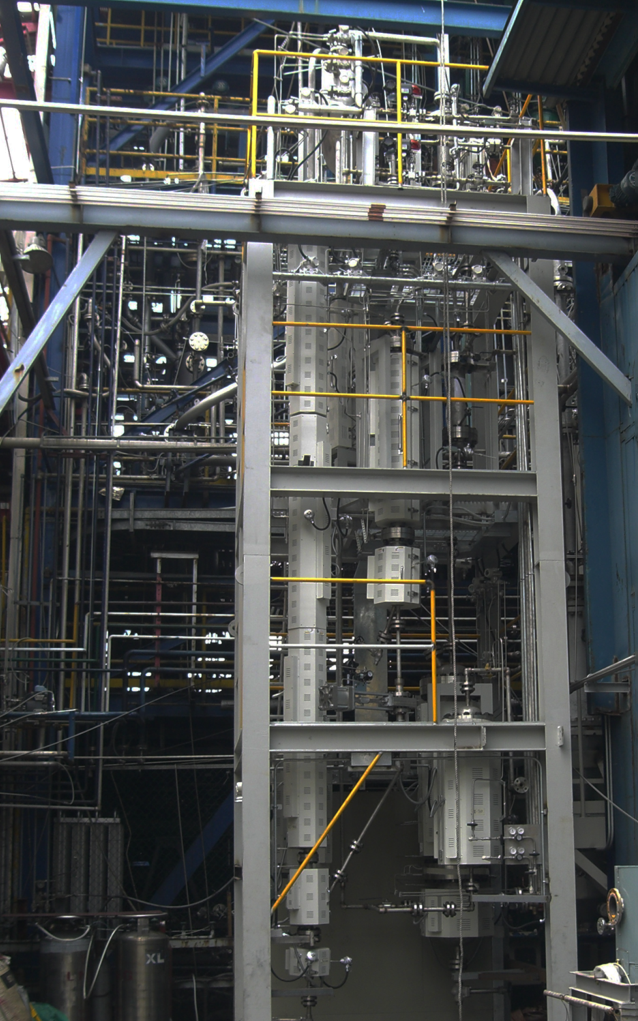

- Pilot Plants

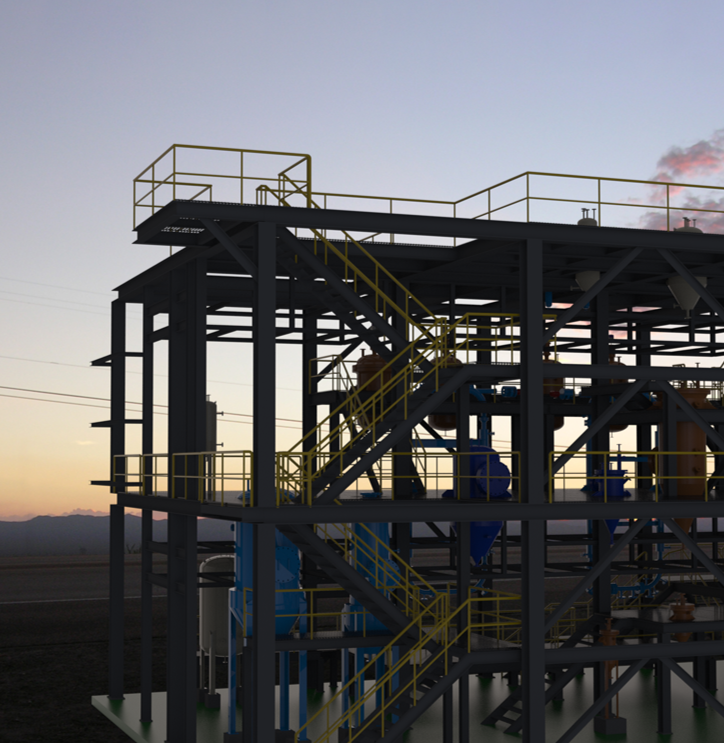

- Demo · Commercial Plants

Classification by Task |

Classification by Project Scale |

|||||

|---|---|---|---|---|---|---|

| E : Engineering | P : Procurement | C : Construction | L : Laboratory | PP : Pilot Plant | DP : Demo Plant | CP : Commercial Plant |

View Key Achievements as a List

| Classification by Task | Classification by Project Scale | |||||

|---|---|---|---|---|---|---|

| E : Engineering | P : Procurement | C : Construction | L : Laboratory | PP : Pilot Plant | DP : Demo Plant | CP : Commercial Plant |

| Client | No. | Year | Project | Classification | Remark |

|---|---|---|---|---|---|

|

1 | 2017 | POSNEP PP-3 ACID RECOVERY SYSTEM | EPC / DP | Posco E&C |

| 2 | 2015 | O2 BACKUP SYSTEM Design / Review consulting services | E | Posco E&C | |

| 3 | 2015 | Subterranean Oil Storage Base Project Consulting (Vietnam) | E | Posco E&C | |

| 4 | 2015 | CO2 SEPARATOR PACKAGE | EPC / DP | Posco Eng. | |

|

5 | 2021 | Polyolefin Pilot Plant | EPC / PP | |

|

6 | 2021 | HPC Laboratory Service Project | EPC / L | |

|

7 | 2018 | FLARE LOAD SUMMARY UPDATE | E | |

| 8 | 2018 | PSV, Rupture Disc, Breather Valve Design | E | ||

| 9 | 2017 | Depentanizer capacity Increase Design | E | ||

| 10 | 2016 | HCR Reaction Section Simulation | E | ||

|

11 | 2020 | KNPC Stripper PSV Dynamic Study | E | |

| 12 | 2020 | HPC ESD Logic Diagram Project | E | ||

한국 탄소 포집 및 격리 R & D 센터 |

13 | 2017 | Establishment of a Wet Pilot Capture Process and Heat Integration Process | E | |

| 14 | 2017 | Manufacturing, Installation of Dry/Membrane Capture Plant | EPC | KIER | |

| 15 | 2016 | Installation of Gas Feed Blower / Heat Exchanger and Aadditional Equipment | PC | ||

| 16 | 2015 | Manufacturing, Installation of a Wet Capture Process on a 100Nm3/hr Scale | EPC / PP | ||

|

17 | 2016 | Solvent Recovery System Additional Construction | PC | |

| 18 | 2015 | Design and Construction of Solvent Recovery System | EPC / CP | ||

|

19 | 2016 | UNIT 7 REVAMPING PROJECT / Additional Construction | EPC | |

| 20 | 2016 | Supervison of C-Project | E | ||

| 21 | 2012 | High Purity N-Hexane Project | EPC / CP | ||

|

22 | 2019 | Detailed Design of Thermodynamic CO2 Methanation Process | E | |

| 23 | 2019 | Economic Viability Assessment of a 1MW-Scale IGFC System | E | ||

| 24 | 2018 | S-Project Pilot Plant | EPC / PP | ||

| 25 | 2015 | 0.1MW-scale CO2 Capture and Additional Facilities | EPC / PP | ||

| 26 | 2015 | Cu / Zn Recovery Pilot Plant | EPC / PP | ||

| 27 | 2013 | WGS Reaction Project | EPC / PP | ||

| 28 | 2013 | MeOH Pilot Plant | EPC / PP | ||

|

29 | 2020 | Basic Design for a 2MW-scale Power-to-Gas (P2G) System | E | |

| 30 | 2012 | IGCC WSA Project | EPS* / CP | * Supervising | |

|

31 | 2013 | PH Recovery Project | EPC / PP | |

| 32 | 2013 | CO2 Capture Absorber Pressurizing Project | EPC / PP | POSCO | |

| 33 | 2012 | Freshwater-Induced Sediment Separation and Recovery Device | E | KIMM | |

|

34 | 2020 | PC (V1) Project | E | |

| 35 | 2018 | SCPE & PO Tank Project | E | ||

| 36 | 2017 | SDC BEP Project | E | ||

|

37 | 2017 | Oil Sand SAGD CPF Pilot Detailed Engineering | E | Elec. / Instr. |

| 38 | 2016 | Oil Sand Pilot Plant Feasibility Study/ Cost Estimation |

E | ||

|

39 | 2015 | Design, Fabrication, and Installation of 0.1MW-Scale CO2 Capture System and Ancillary Equipment | EPC / PP | |

| 40 | 2014 | Manufacturing, Installation of a 1MW-Scale Pollution Gas Purification Facility | EPC / PP | ||

| 41 | 2013 | 0.1MW Test Bed CO2 Compression and Liquefaction Process Design | E | ||

|

42 | 2016 | Basic Design for a COG Purification Facility for H2S Removal | E | |

| 43 | 2015 | CO2 Capture Facility Using DME | EPC / PP | ||

| 44 | 2014 | Modification and Enhancement of CO2 Absorption Device for COG Treatment | PC | ||

| 45 | 2014 | Basic Design of CO2 Capture Process Using Liquid Aammonia | E | ||

| 46 | 2013 | SNG CO2 Removal Project | EPC / PP | ||

| 47 | 2012 | DMC Project, Design and Construction | EPC / PP | ||

| 48 | 2011 | Design, Fabrication and Construction of 50Nm3/hr SNG Project | EPC / PP | ||

|

49 | 2018 | Development of CO2 Treatment Process (PDP) and Economic Feasibility Assessment for a Natural Gas Plant with a Capacity of 200t/hr | E | |

| 50 | 2018 | Optimal Process Aanalysis for Improving the Efficiency of a Chemical Looping Combustion Power Generation System | E | ||

| 51 | 2018 | Performance Analysis of a Chemical Looping Combustion Power Generation System with Configuration Changes and Operational Variations | E | ||

| 52 | 2017 | 0.5MW CLC Project | EPC / PP | ||

| 53 | 2016 | Manufacturing, Installation, and Optimal Process Analysis of a 0.5MW Chemical Looping Combustion Power Generation | E | ||

| 54 | 2015 | Design of Utility Systems Including Pollution Gas Purification | E | ||

| 55 | 2015 | Maintenance of a 1MW Pollution Gas Purification Process | E | ||

| 56 | 2015 | Manufacturing and Commissioning of SOUR WGS Reaction System | EPC / PC | ||

| 57 | 2013 | H2S Removal Project | EPC / PP | ||

|

58 | 2014 | Commissioning Supervision of PFC Decomposition Facility | E | |

| 59 | 2014 | Design Supervision of PFC Decomposition Facility | E | ||

| 60 | 2014 | Supervision of NOX Abatement Project Manufacturing | E | ||

|

61 | 2020 | Ultrason MOC Engineering | E | |

| 62 | 2020 | TDI PSV Scenario / Calculation | E | ||

| 63 | 2019 | Ultrason PSV Scenario / Calculation | E | ||

| 64 | 2017 | Reviewing PSV Capacity for AnMNB Plant Expansion | E | ||

| 65 | 2015 | HYCO PSV Scenario Work | E | ||

|

66 | 2017 | HTC SM3 BEP Support : CAD, P&ID 용역 | E | |

| 67 | 2013 | KNPC CFP Project Design | E | ||

|

68 | 2019 | Design of New Polymer Pilot Plant | E | |

| 69 | 2018 | PIB Basic Engineering PACKAGE | E | ||

|

70 | 2018 | MO DECOMM Project | C | |

KEPCO Nuclear Fuel |

71 | 2017 | UF6 Cylinder Cleaning and Periodic Inspection Facility | EPC / PP | |

|

72 | 2020 | PSC Pilot Plant Basic Engineering | E | Russia |

|

73 | 2011 | Detailed Design and Construction of NH3 Stripping Package within the Wastewater Treatment Facility | EPC / CP | |

|

74 | 2019 | MDI Expansion Basic and Detail Engineering | EPC / CP | |

|

75 | 2011 | Process Improvement for Enhanced Productivity in MOD-MDI and VARIANT Production | EPC / CP | |

|

76 | 2008 | PB-I Project | EPC / PC |