Core Business - Modular Plant

Rapid & Cost-effective Method for Building a Plant

The modular approach is one of the most efficient and cost-effective methods for constructing a factory. Most notably, on-site assembly takes only 1-2 weeks, significantly reducing construction time. Since all manufacturing processes are carried out in well-equipped specialized factories, the quality of equipment and plants is superior. Additionally, there is no need to worry about unexpected variables that may arise on-site.

1. Cost Savings: By minimizing utility facilities for production on-site and addressing issues with labor supply based on site conditions, construction costs are reduced overall due to the shortened construction period, despite a slight increase in material and fabrication costs resulting from considerations for module transportation and a sturdier structure.

2. Clear Accountability: In on-site construction, multiple companies collaborate, which can sometimes lead to ambiguity in accountability. However, modular construction ensures clear accountability.

3. High Quality: As the manufacturing process is less affected by on-site conditions, superior quality construction is possible. With all fabrication processes performed by experienced professionals in well-equipped factories, the reliability of fabrication is enhanced, and construction time is reduced.

4. Site Safety: Modular construction avoids many fabrication processes that are difficult to perform on-site, resulting in a much safer work environment. Additionally, it minimizes the impact on existing plant operations during the installation of new plants, reducing security concerns associated with construction personnel.

5. Mobility of Modules: In case of future plant expansion or relocation, modular structures allow for flexible operations.

Modularization During the Design Phase

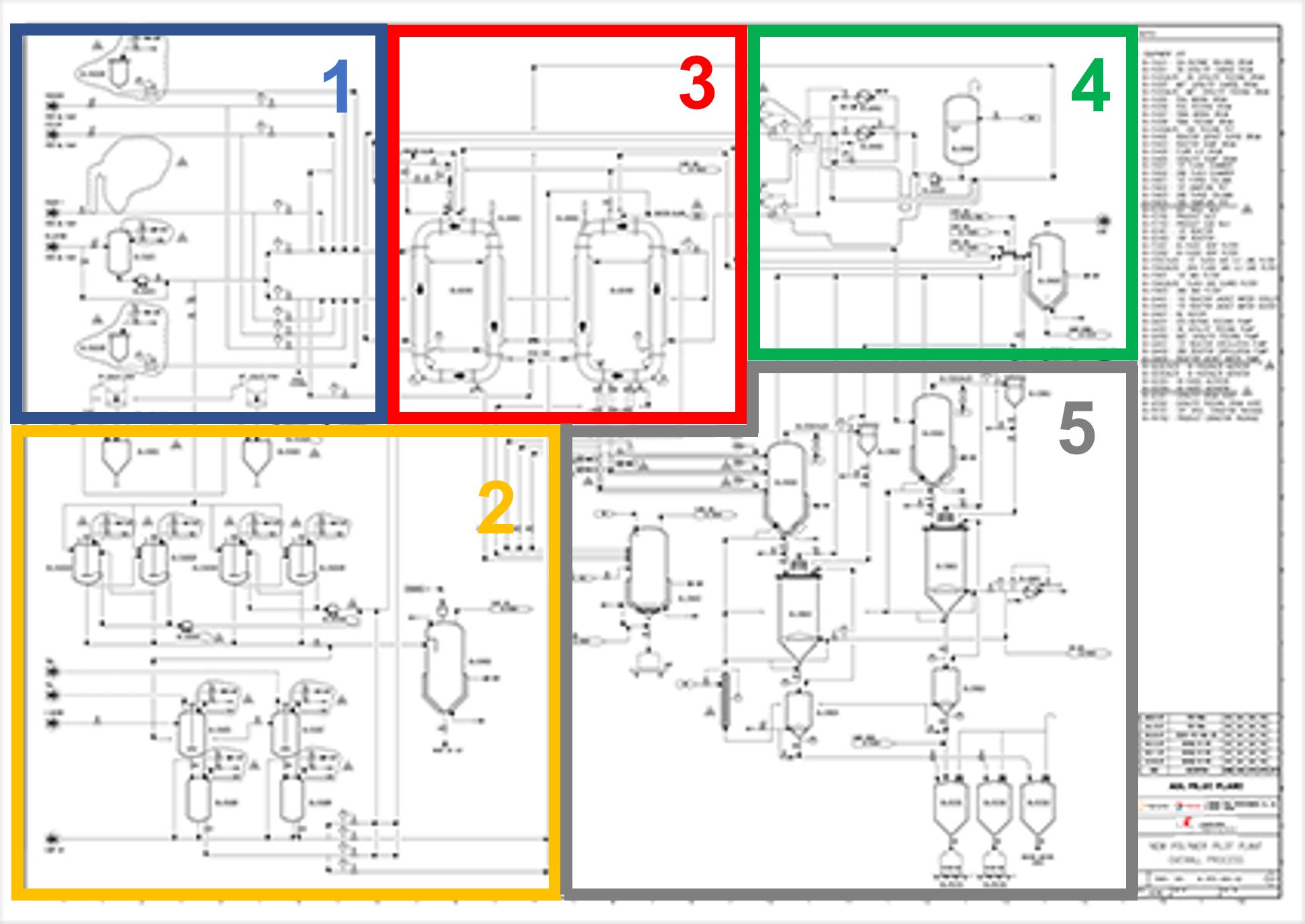

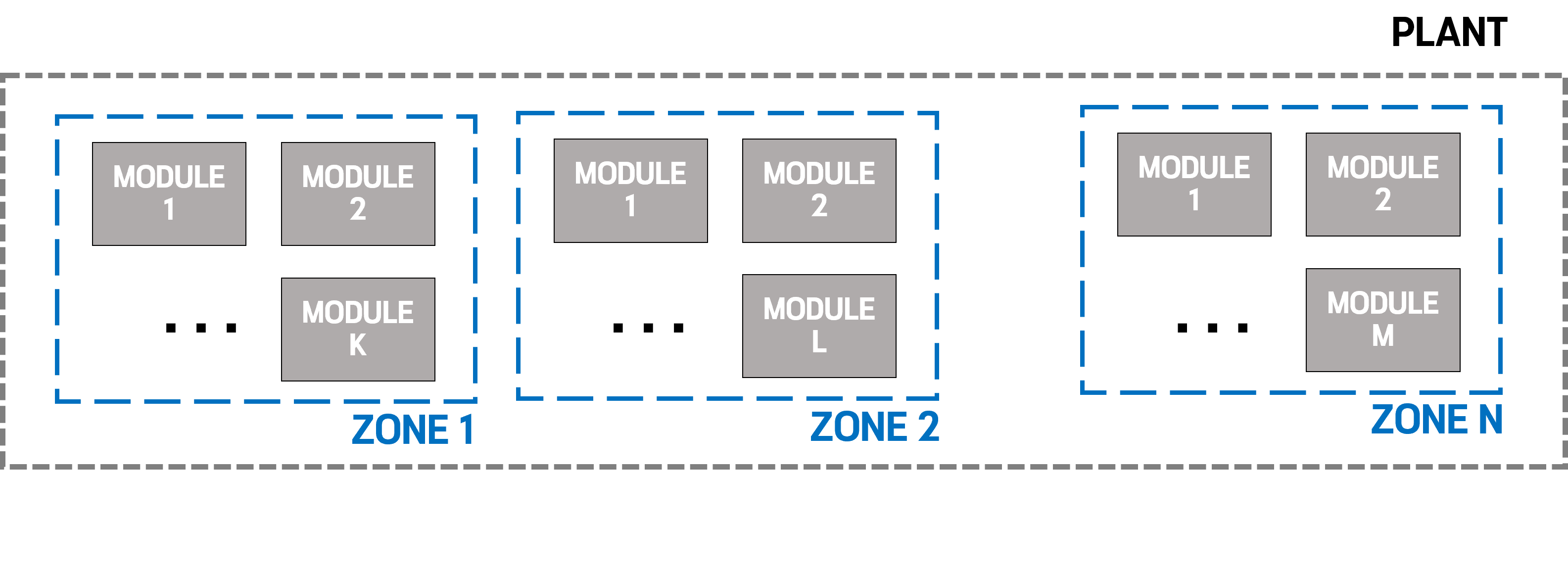

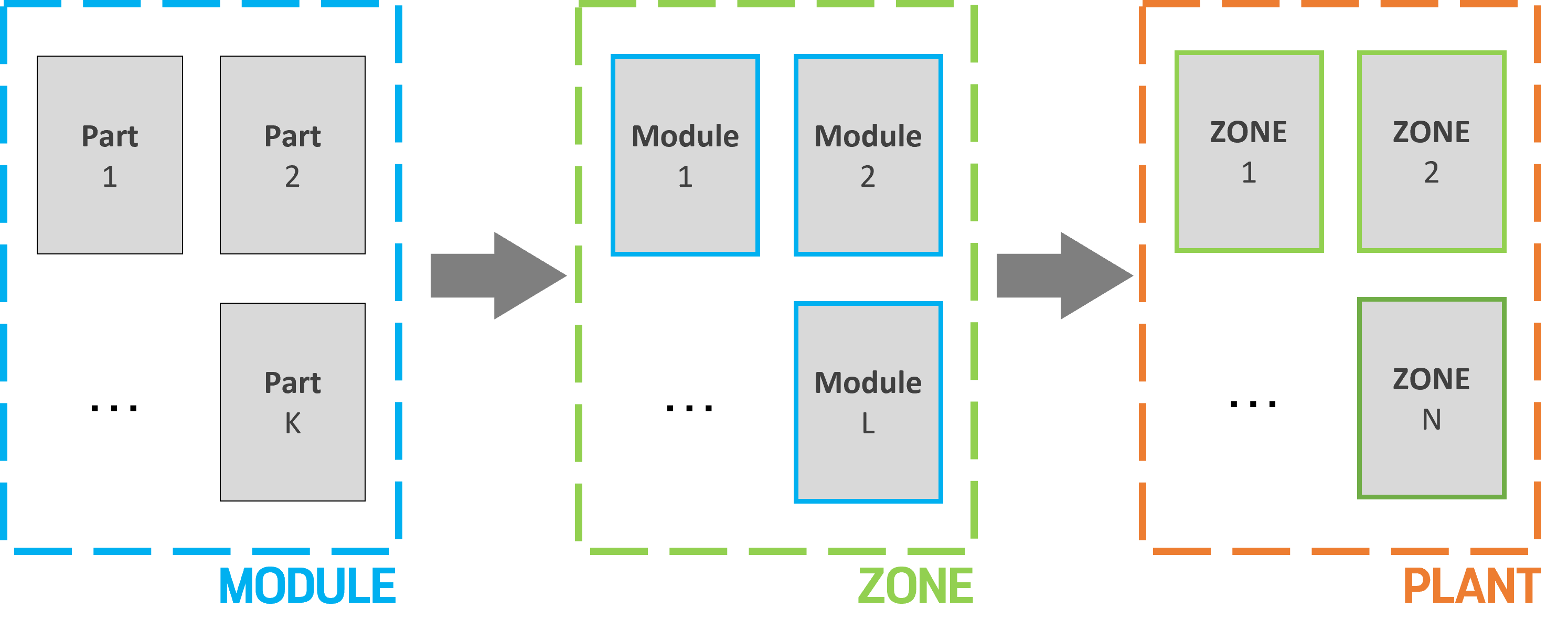

There are two main methods for modular construction. The most common approach is to consider modularization from the design phase. This involves dividing the plant into several zones during the PFD stage, then further breaking down each zone into multiple modules for fabrication, before creating P&IDs.

(Example)

ZONE 1 : Feeding Zone ( Prepare Raw Materials )

ZONE 2 : Catalyst Zone ( Prepare / Store Catalyst and Cocatalyst )

ZONE 3 : Reactor Zone ( Producing Polymerized Products )

ZONE 4 : Product Zone ( Transfer the Products to the Conveyor )

ZONE 5 : Utility Zone ( Prepare Nitrogen, Steam, Water, etc. )

Modules consist of connecting multiple pieces of equipment via piping, including instrumentation and electrical wiring. The location of modules is determined based on major or large equipment. Within modules, pipes are connected with flanges to link adjacent modules. Modules include wiring for electrical and instrumentation purposes, with switchboards included to ensure proper connection to adjacent modules.

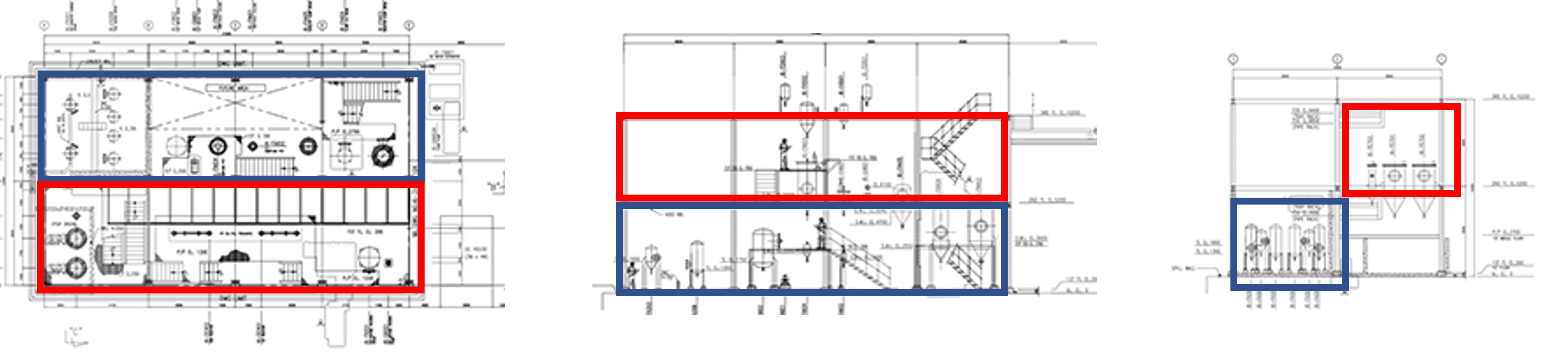

Modularization During Construction Phase

Even if modularization is not considered during the design phase and the plot plan is completed, modular construction is still feasible. In this case, the plot plan is divided into suitable sizes for modularization to proceed.

Modular Plant Construction

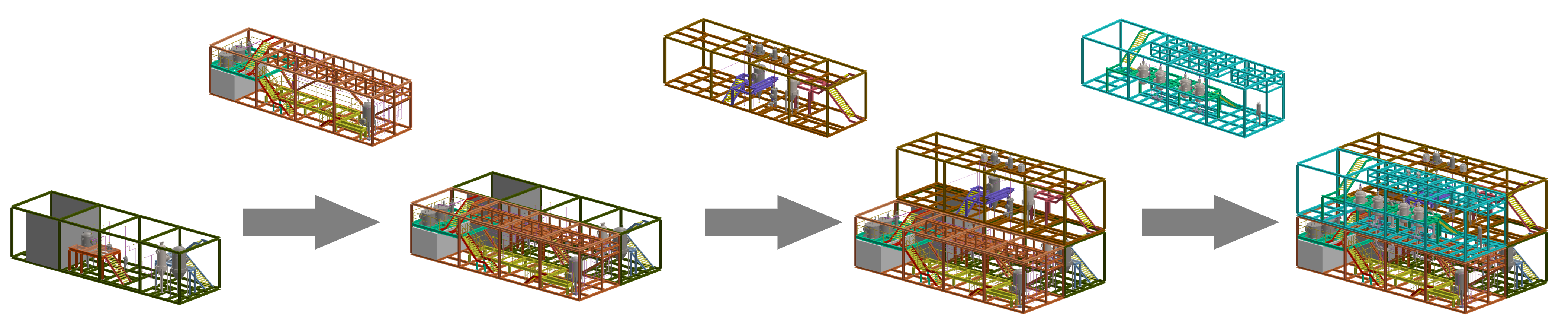

Module assembly follows the reverse process of module design. It starts with the smallest equipment and builds modules, then assembles these modules to complete zones. When all zones are complete, the plant is considered finished..

In this process, a lot of expertise is required. To ensure quick and easy assembly, each module needs to be tagged with a unique number. If there are accessories transported separately from the module, clear tags should be written on the module for identification. Matching symbols are also necessary on-site to easily identify where piping connections are made. Temporary structures are needed to absorb vibrations and shocks during module transportation. It's essential to check if frames are deformed during lifting or transportation. Every step must be meticulously executed to maximize the advantages of module assembly.