Classification by Tasks

CES covers all stages of the project. This includes conducting feasibility studies and cost estimations during the project review phase, followed by basic and detailed design stages, ensuring meticulous review of drawings, and finally, ensuring excellence in procurement and construction based on thoroughly reviewed drawings. Regardless of the stage your project is in, CES will strive to assist in its success.

Engineering |

Procurement |

Construction |

|

|

|

|

Consulting Feasibilty Study Basic/FEED |

Equipment Procurement Schedule & Budget Management, etc. |

Permitting Site & Personal Management, etc. |

Classification by Scale

CES has accumulated extensive experience by undertaking various projects ranging from small to large scale. We meticulously execute projects of all sizes, including small-scale R&D projects, pilot plants for process improvement and catalyst development, and even large-scale demonstration/commercial plants. We ensure thorough and seamless execution regardless of the scale.

Laboratory |

Pilot Plant |

Demo/Commercial |

|

|

|

Laboratory EPC Gas Supply / Analysis Equipment Consulting / Educations etc. |

For Use in Process & Catalyst Research Adaptable for Multi-purpose Applications |

Process Improvement / Capacity Expansion Facility Addition etc. |

Classification by Industrial Sector

CES has completed numerous projects across various sectors, with a focus on chemical/petrochemical, environmental, energy, and power generation fields. Our core projects include polyolefin pilot plants in the petrochemical sector, carbon capture/utilization processes in the environmental field, and clean hydrogen production processes for future energy demands.

Chemical/Petrochemical |

Environmental |

Energy / Power Generation |

|

|

|

|

Polymer Chemical Pharmaceutical, etc. |

CO2 Capture/Recovery/Separation VOC, WGS, Desulfurization, etc. |

DME, Ammonia-Hhydrogen Integrated Ggasification Cycle, etc. |

Special Engineering

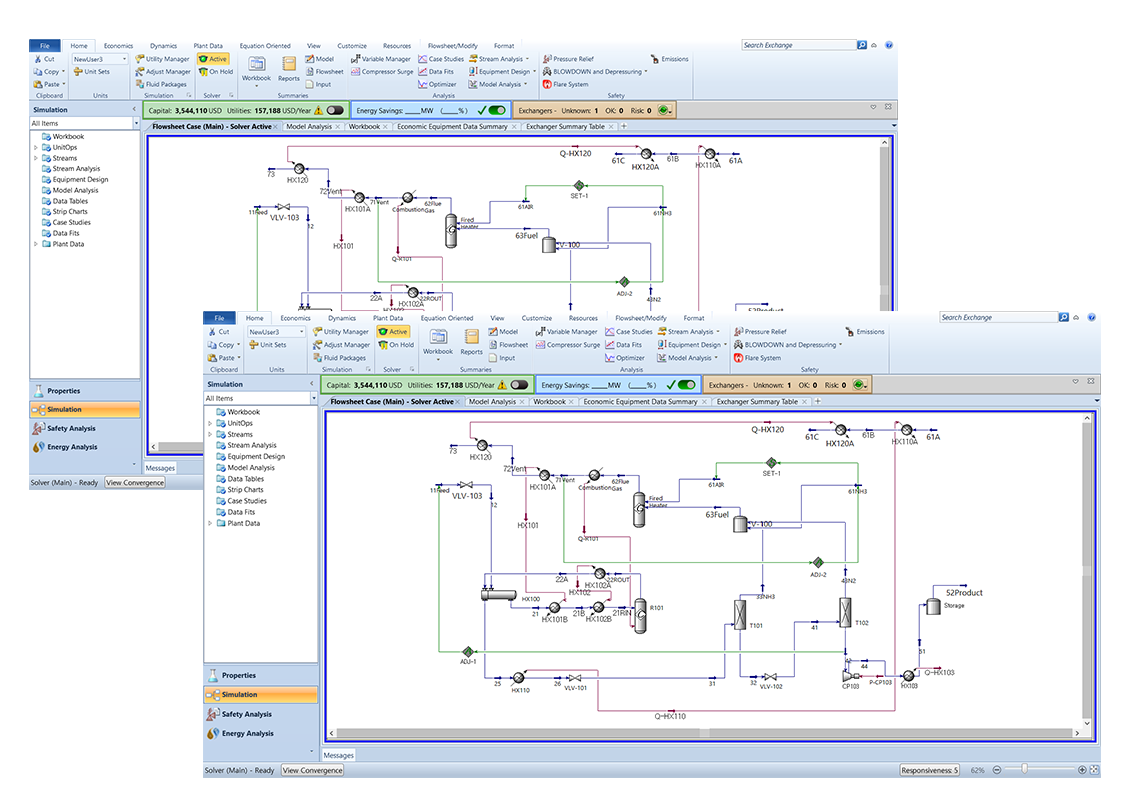

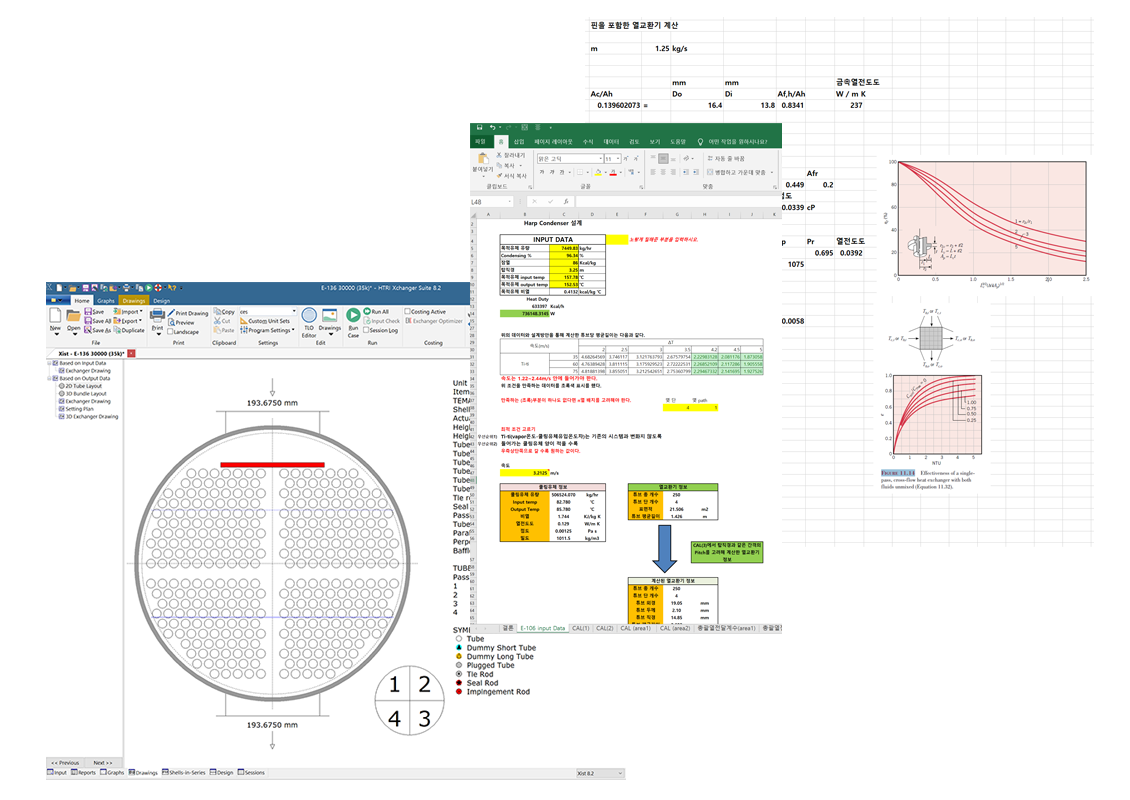

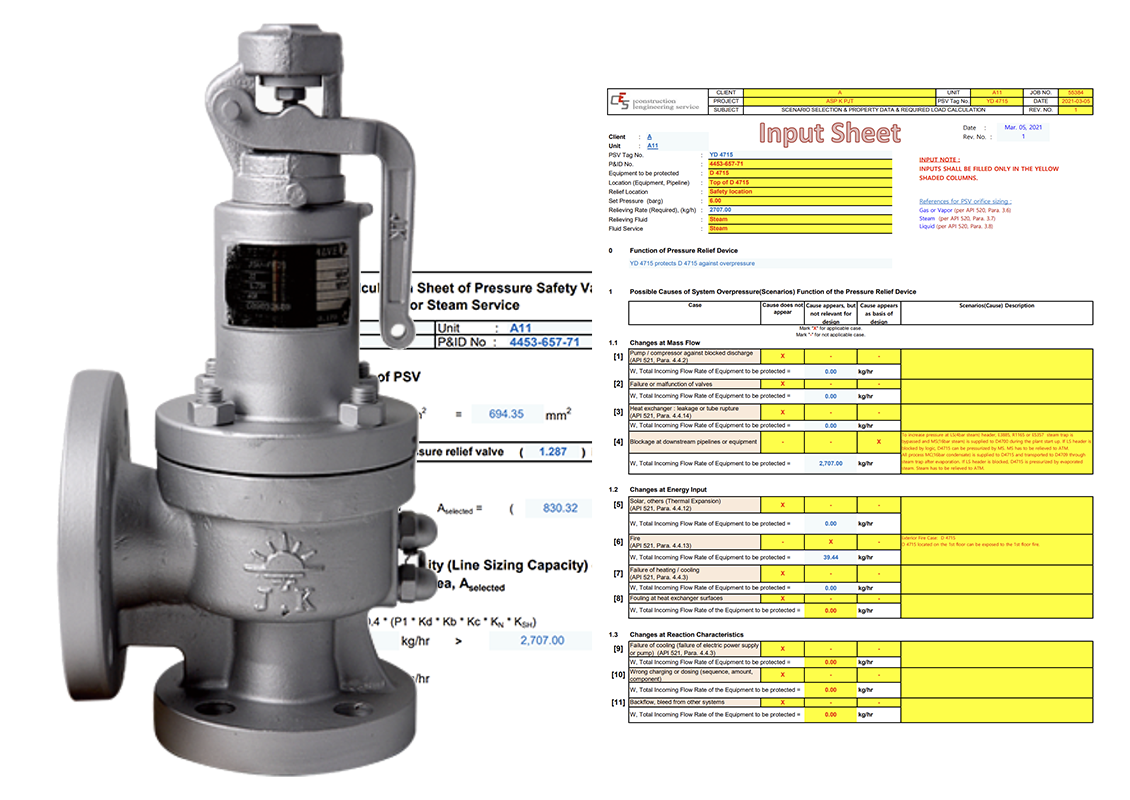

CES specializes in process engineering, interpreting complex heat transfer and fluid phenomena within plants. We conduct precise process simulations using software like ASPEN and PRO II. We can utilize HTRI for designing and thermal rating of heat exchangers, and we're capable of interpreting heat transfer theory for non-conventional types of heat exchangers as well.We are also recognized for our expertise in scenario review and calculation for PSVs, PRVs, and have undertaken projects for BASF, GS Caltex, Intec, and others.

Process Analysis |

Heat Transfer & Fluid Flow |

PSV Calculation / Scenario Review |

|

|

|

|

Process Analysis, Process Simulation Aspen Hysis, Pro II |

Heat Transfer and Fluid Analysis Using CFD Design and Thermal Rating Using HTRI Analysis of Non-Conventional Types |

Review of PSV/PRV/RD Scenarios Rupture Disc Sizing, Back Pressure review Analysis of Flare Load Summary |