Core Business - Polyolefin / Polybutene Pilot Plant

The Polyolefin Market, Growing and Increasingly Competitive

The global plastic production exceeds 300 million tons annually, with over half being polyolefin products like polyethylene and polypropylene. Polyolefins are favored for their cost-effectiveness and superior properties, driving their increasing consumption. This surge in demand has intensified competition among companies striving for market dominance.

To thrive in this competitive landscape, companies need efficient processes, superior product properties, and optimized catalysts for production. These are typically acquired through various experiments and trial-and-error processes. However, conducting such experiments in commercial plants is nearly impossible. Hence, many companies have established specialized pilot plants for research and development (R&D) purposes.

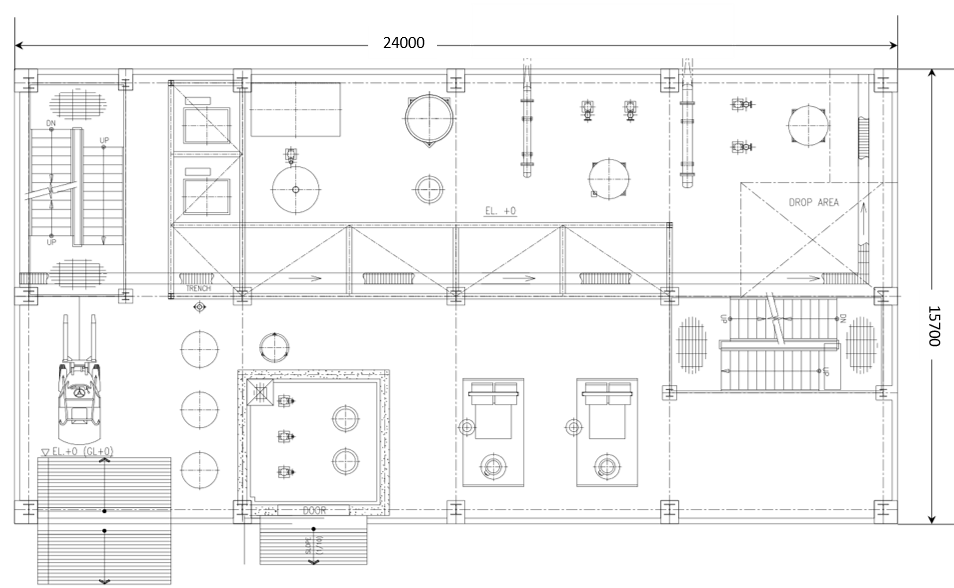

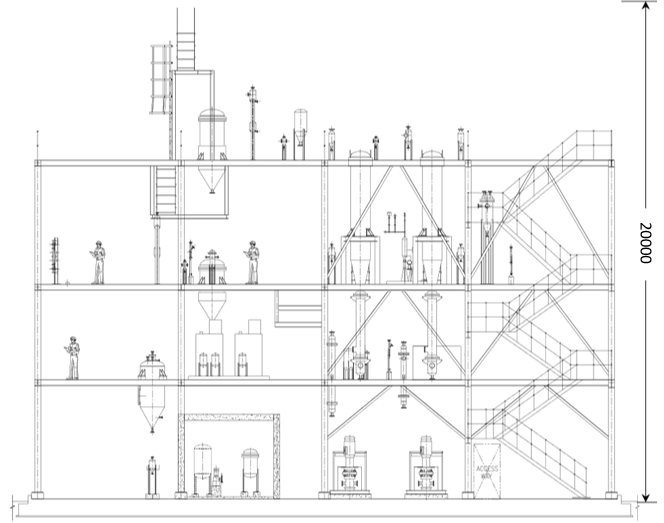

Pilot plants are merely smaller in scale, but they are equivalent to commercial plants in terms of producing products. Therefore, almost all equipment that goes into commercial plants must be installed in pilot plants as well. The smaller scale and production volume typically mean that piping must be constructed using smaller diameter tubes instead of conventional pipes. Additionally, even small fluid flows must be precisely controlled. As pilot plants are used for process improvement and product development, there is much to consider from the design stage to allow for changes in catalysts, processes, and operating methods.

So, contrary to what many might expect, designing and constructing a pilot plant can actually be more challenging than a commercial plant. CES has accumulated extensive experience in the field of pilot plants. As an exceptional specialist, we can provide reliable solutions from design to construction for the pilot plants you desire.

CES's Polyolefin Pilot Plant

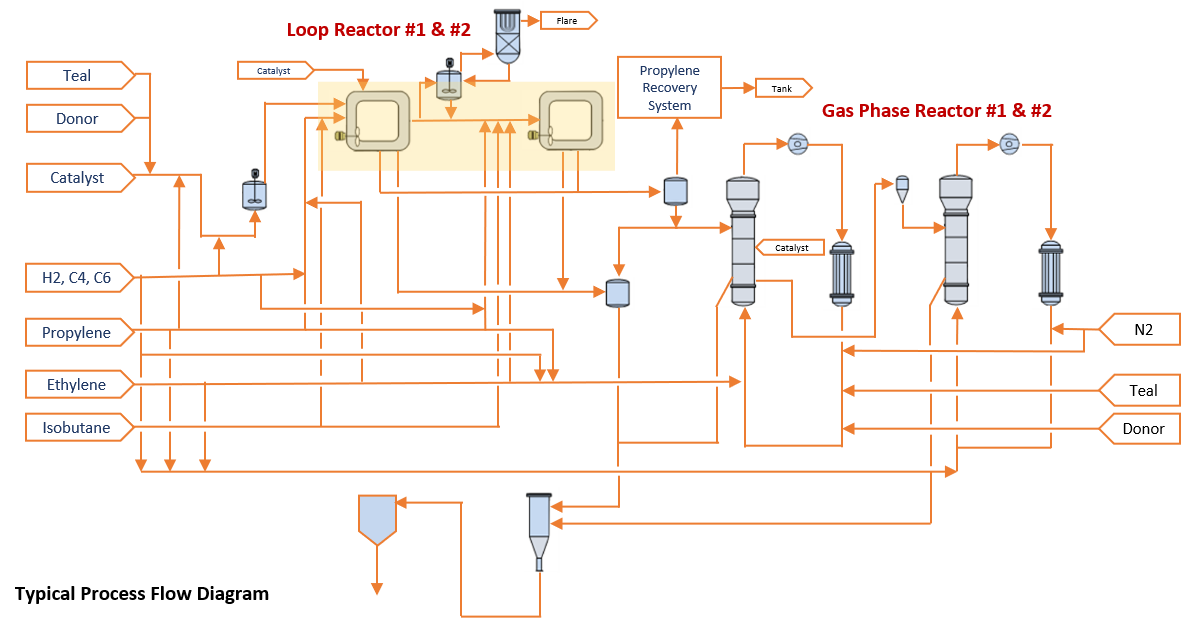

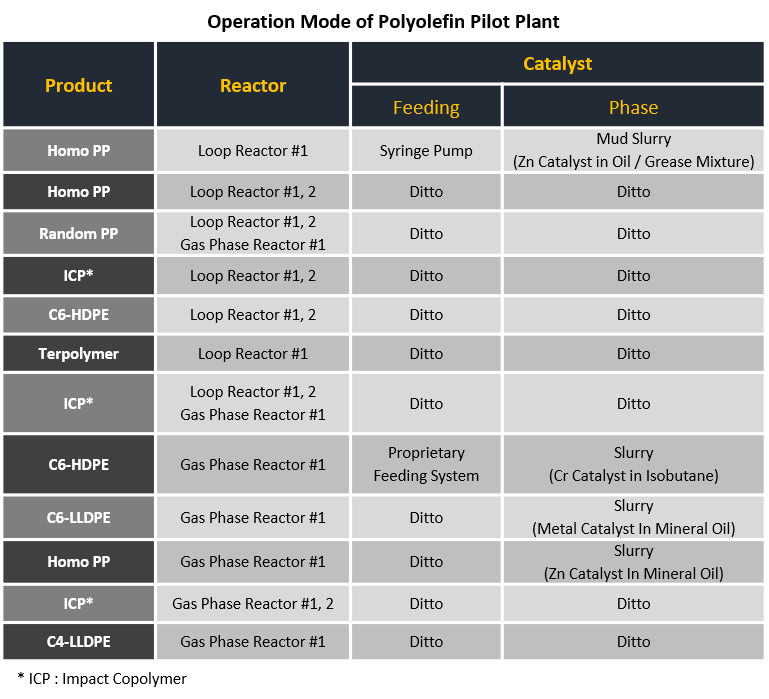

CES designs processes according to customer requirements, allowing for the selection of optimal configurations for gas-phase PE or PP, slurry, and bulk PP processes.

CES's polyolefin pilot plant offers exceptional reliability in supplying various types of catalysts and auxiliary catalysts, including the capability for supplying small-scale solid catalysts.

CES's service doesn't end with construction. Experienced engineers in relevant fields assist with commissioning and operational modifications.

| Client | Project | Experience |

|

PB1 Commercial | EPC |

|

PIB Commercial | Basic Engineering |

| ADL Pilot | Detail Engineering | |

|

PO Pilot | Detail Engineering |

|

PO Pilot | Conceptual Design |

| PO Pilot | Basic Engineering | |

|

PO Pilot | Basic Engineering |

| PO Pilot | EPC |